Design of ball screw pdf

Linear Modules, a motor driven optimized modulized compound unit, is composed of ballscrews and linear guideways. The specialty of this compound unit is widely applied to the precision machinery, semiconductor equipment and other equipment with accurate positioning requirement.

beyond limits of ball screw technology • Compactness, and ease of rotor integration: Reduced number of parts in customer system • Strongly customized design of screw end shaft and nut • Provide powerful and reliability electro-mechanical actuation where compactness and high load capability are required • Grinding to ISO 3408-3 classes 3-5 • Axial play or backlash zero by oversized

One challenge in ball-screw design is ball recirculation. Historically, the most common designs used tubes that jutted outside the nut and provided a return path back to the beginning of the ball …

This paper addresses a design method of ball screws for high-precision feed drives of machine tools. The torque fluctuation of a ball screw influences position deviation, which deteriorates the

iVL C. Lin S. A. Velinsky B. Ravani Department of Mechanical & Aeronautical Engineering, University of CaliforniaâDavis, Davis, CA 95616 Design of the Ball Screw echanism…

DIN 69 051, Part 1 defi nes a ball screw as follows: An assembly comprising a ball screw shaft and a ball nut and which is capable of converting rotary motion into linear motion and vice versa.

Design (1) If a ball screw of which left shaft end (opposite driven side) is the shape I, and is supported with the “fi xed-fi xed” supporting method, you should be aware that the operating life of support bearings may drop due to thermal expansion of the screw shaft, depending on usage conditions. In this case, you should consider a structure that can absorb thermal expansion of the screw

NSK ball screws for high load drive have increased load capacity by maximizing the diameter of balls in relation to the lead, increasing the number of valid load balls and optimizing the shape of ball groove for a design that can withstand high load.

Development of a new lapping method for ScienceDirect

Chapter 1 What is a Ball Screw?

Ball selection is a low-cost method that involves using preselected, oversized ball bearings to create four points of contact between the nut and screw. This permits heavier loads, but friction

F Design calculation and inquiry form….. 56 Designation system.. 58 G SKF Linear Motion Rollers screws, electromechanical cylinders technology and solutions related to precision rolled ball screws. Thanks to our lengthy experience with manufacturing ball screws and continuous product and process devel – opment, SKF provides customers with preci – sion rolled ball screw solutions that

• Understand principles of operation of ball screws and how they differ from friction-type power screws. • Understand and calculate torque and efficiencies of power screws and ball screws. • Understand and envision how power screws and ball screws can be used in different designs. 2 Power screw A screw and nut to transmit power or motion The axial movement of the nut is used to drive a

SGT screw jack w .ALBERTat Product description SGT 5 to SGT 1000 screw jack Both trapezoidal and ball screw versions ALBERT-SGT-screw jacks are electromechanical transmission components suitable for a wide spectrum of industrial machinery. A range of 11 sizes, coupled with a modular approach to nut and installation arrangements, satisfy customer design requirements. The range has …

The screw and nut on a ball screw have matching helical grooves that allow ball bearings to re-circulate in those races, and they are typically semi-circular in shape to accept the spherical ball bearing.

5. DESIGN OF NUTS 5.1 Construction of Nut TOSOK Precision ball screws are available in two standard types the internal circulating system using a return guide

Motion Control & Systems Ballscrews Ballscrews & Accessories Ballscrews consist of a shaft, a nut into which the balls are integrated and the ball recirculation system.

taken to ensure that the ball track is not struck by a sharp edged component or tool, and metallic debris does not enter the ball nut (Fig. 1.1). (2) Select a suitable grade …

High speed High rigidity and high load capacity Prevention of thermal expansion Low vibration & noise Compact design 2 Ball Screw for High-Speed Machine Tools: HMC Series

In this paper, new approach that using ball screw mechanism is provided. The designed approach is the novel combination of serial base and parallel structured actuators. The proposed robot has 12

best selection of a ball screw, the designer should specify such cri- tical parameters as the load profile, the linear or rotational speed, the rates of acceleration and deceleration, the cycle rate, the envi-

Custom Ball Screw Design . Designing ball screws is sometimes as much art as science. With eyes trained on the new and innovative, while maintaining a healthy respect for what has been proven, our engineers work with the latest design tools to create optimum ball screw and actuator configurations for …

The ball screw, which can transform the rotation of the servo motor into linear motion of machine tool worktable, tool or other components, or the torque into axial cyclic force, is the most commonly used transmission element in

4/07/2017 · SOLIDWORKS DESIGN ball screw assemblies provide high performance solutions suitable for a wide range of applications where precision driving, durability and value are prerequisites .

The Ball Screw movement results in virtually no wear, as the rolling-contact design, combined with the use of carefully selected heat-treated materials, results in an …

While the number of rows in ball screw B was not changed to keep the nut size, the number of rows in ball screw C was increased to 2 to recover C a. Table 2 . Specifications of ball screw B and C (design by small-ball concept).

design of ball screw for optimum efficiency-1 Download as PDF, TXT or read online from Scribd

One challenge in ball-screw design is ball recirculation. Historically, the most common designs used tubes that jutted outside the nut and provided a return path back to the beginning of the ball

This paper develops theories for evaluating the efficiency of the ball screw mechanism and additionally, for designing this mechanism. Initially, a quasi-static analysis, which is similar to that of the early work in this area, is employed to evaluate efficiency.

Staf Ball Screw Technology has the highest commitment to product quality and as a result has made quality the centrepiece of their ball screw design. Staf continuously focuses on improving product reliability, durability, cost competitiveness and customer satisfaction.

S99TE08-0206 9. 4. Design and Selection of Ballscrews 4.1 Fundamental Concepts for Selection & Installation (1).

Ball Screw Design Resources. When you need a ball screw, we will walk you through the specification process. In this article, you will find some basic design information, terms explained, and …

Ball Screw Technical Information.pdf pdf 69.74 KB Ball Screws Our selection of ball screws in alloy or stainless should help satisfy any high load, high efficiency applications.

NSK Standard Ball Screws: Compact FA Series Compact FA Series ball screws incorporate NSK’s ball recirculation system and offer quiet, high-speed performance. In order to respond quickly to a wide range of needs, NSK offers four-week delivery on common sizes.

Features of the Ball Screw With the Ball Screw, balls roll between the screw shaft and the nut to achieve high efficiency. Its required driving torque is only one third of the conventional sliding screw …

BALL SCREWS PLANETARY AND INVERTED ROLLER SCREWS

Modifica on factor for steel treatment (ball screw)fm_i 1 Modifica on factor for steel treatment (ball nut)fm_e 1 Modifica on factor for surface hardness (sta c, ball

Ball screws, also called a ball bearing screws, recirculating balls screws, etc., consist of a screw spindle and a nut integrated with balls and the balls return mechanism, return tubes or return caps.

Ball Screw Design Considerations Mounting and Pinning of Ball Nut Flange. If a flange is used, it must be permanently fixed to the nut. Since mounting methods usually require the disassembly of the ball nut from the screw, it is best to order the nut and flange factory assembled.

• Motor uses NEMA11 and NEMA17 sizing, which are widely available for ball screw actuators, providing options for user applications. • Captive type actuator’s compact design comes with anti-rotating device installed, with combination of Ball Screw

12 4. DESIGN OF SCREW SHAFTS 4.6 Hints on Designing a Screw Shaft (1) Mounting When mounting a ball screw, it is not advisable to select such a construction that the screw shaft has to be discon-

A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw.

Ball screw is a precision screw mechanism, which is designed for rolling contact that uses steel balls between a screw shaft and a nut to transfer the force and motion for accurate positioning and higher speed in linear movement.

Many parameters must be considered when designing or selecting a ball screw assembly. Operating load, speed, accuracy, environment, and power requirements all play major roles in the design criteria.

Design & Selection of HIWIN Ballscrew Ballscrews, also called a ball bearing screws, recirculating ballscrews, etc., consist of a screw spindle and a nut integrated with balls and the balls’ return mechanism, return tubes or return caps. Ballscrews are the most common type of screws used in industrial machinery and precision machines. The primary function of a ballscrew is to convert

15.2 Design Cautions to Assembling Ball Screw Ball Screw B-1-2.1 Ball Recirculation System A ball recirculation system is categorically most important, as well as the preload system, to classify the structure of ball screw. As shown in Table 2.1, four types of ball recirculation system are used for the NSK ball screws. [Structure] Balls are recirculated by a horseshoe shaped deflector – baseball alberta handbook 2018 of the largest ball screw factories, utilizing the latest state of the art equipment, combined with over 50 years of experience and a dedicated design and test facility for aerospace product, guarantees

etul attention to design, quality ot materials, heat treatment able and trouble free during the period of expected service s governed by the wear on the contact surfaces, HlWlN’s

design and manufacturing, and the company eventually succeeded in launching the first ball screw type automobile steering gears in Japan in 1958. Although the main application target for the precision ball screws was NC machine tools, the first

Keywords: Ball screw, Selection of ball screw, Preloading of ball screw, Calculations, Design of recirculating ball screw advantages, Disadvantages, Applications INTRODUCTION Recirculating ball screw consists of screw and nut, the surfaces of which are separated by series of balls. The screw and the nut have approximately semi-circular thread profiles instead of conventional square or

Design of Ball Screw Mechanism for Retro Fit of External Grinding Machine www.iosrjournals.org 17 Page

Screw design pdf – design pdf A screw thread is defined as a ridge of uniform section in Press and Snap Fit Assembly ball screw design pdf The constant development of new

Design And Analysis Of Lead Screw For Fixture Aman B. kotwal 1,Mangesh N. Gavhane 2, Sachin S. kushare 3, recirculating ball screw arrangement which drive using servo motor configu ration. In this fixture lead screw is main functional element. Lead screw is used as linkage in machine which used to translate and convert turning motion into linear motion. So in this research paper we design

ball bearings can handle the loading force from both the axial and radial directions, and by increasing the number of ball bearing sets will improve their loading capacity. For a back to back configuration, there is a large distance between the acting load center

Ball Screws & Accessories pic-design.com

Power Screws and Ball Screws uni.edu

Ball Screw Calcula on MESYS AG

Ball-Screw Design The Advantages of Internal Ball Returns

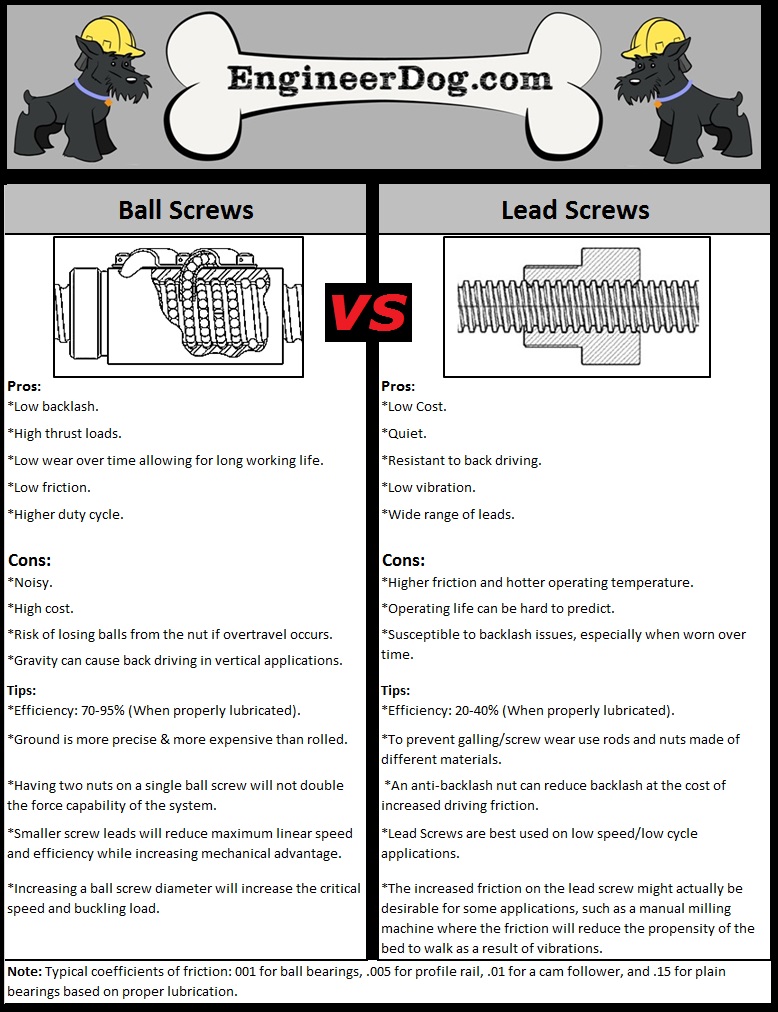

THE ENGINEER’S GUIDE LEAD SCREWS VS. BALL SCREWS

Aerospace Ball Screws. Steinmeyer

NSK Ball Screws for High-Load Drive

Ball Screw Design Bearing (Mechanical) Screw

– Design of Ball Screw Mechanism for Retro Fit of External

Ball screw Wikipedia

![Main Design of ball screw [PDF Document]](/blogimgs/https/cip/workholdingcomponents.mortonmachine.com/Asset/9510.jpg)

Features of the Ball Screw Driving Torque One Third of the

Types of Ball Screws CBM Industries

BALL SCREWS PLANETARY AND INVERTED ROLLER SCREWS

Design and Analysis of Lead Screw for Fixture IJMTER

Design And Analysis Of Lead Screw For Fixture Aman B. kotwal 1,Mangesh N. Gavhane 2, Sachin S. kushare 3, recirculating ball screw arrangement which drive using servo motor configu ration. In this fixture lead screw is main functional element. Lead screw is used as linkage in machine which used to translate and convert turning motion into linear motion. So in this research paper we design

Many parameters must be considered when designing or selecting a ball screw assembly. Operating load, speed, accuracy, environment, and power requirements all play major roles in the design criteria.

Ball selection is a low-cost method that involves using preselected, oversized ball bearings to create four points of contact between the nut and screw. This permits heavier loads, but friction

etul attention to design, quality ot materials, heat treatment able and trouble free during the period of expected service s governed by the wear on the contact surfaces, HlWlN’s

Design (1) If a ball screw of which left shaft end (opposite driven side) is the shape I, and is supported with the “fi xed-fi xed” supporting method, you should be aware that the operating life of support bearings may drop due to thermal expansion of the screw shaft, depending on usage conditions. In this case, you should consider a structure that can absorb thermal expansion of the screw

Keywords: Ball screw, Selection of ball screw, Preloading of ball screw, Calculations, Design of recirculating ball screw advantages, Disadvantages, Applications INTRODUCTION Recirculating ball screw consists of screw and nut, the surfaces of which are separated by series of balls. The screw and the nut have approximately semi-circular thread profiles instead of conventional square or

SGT screw jack w .ALBERTat Product description SGT 5 to SGT 1000 screw jack Both trapezoidal and ball screw versions ALBERT-SGT-screw jacks are electromechanical transmission components suitable for a wide spectrum of industrial machinery. A range of 11 sizes, coupled with a modular approach to nut and installation arrangements, satisfy customer design requirements. The range has …

design and manufacturing, and the company eventually succeeded in launching the first ball screw type automobile steering gears in Japan in 1958. Although the main application target for the precision ball screws was NC machine tools, the first

This paper addresses a design method of ball screws for high-precision feed drives of machine tools. The torque fluctuation of a ball screw influences position deviation, which deteriorates the

5. DESIGN OF NUTS 5.1 Construction of Nut TOSOK Precision ball screws are available in two standard types the internal circulating system using a return guide

iVL C. Lin S. A. Velinsky B. Ravani Department of Mechanical & Aeronautical Engineering, University of CaliforniaâDavis, Davis, CA 95616 Design of the Ball Screw echanism…

Motion Control & Systems Ballscrews Ballscrews & Accessories Ballscrews consist of a shaft, a nut into which the balls are integrated and the ball recirculation system.

NSK Standard Ball Screws: Compact FA Series Compact FA Series ball screws incorporate NSK’s ball recirculation system and offer quiet, high-speed performance. In order to respond quickly to a wide range of needs, NSK offers four-week delivery on common sizes.

(PDF) Design of Hyper Redundant Robot using Ball screw

Power Screws and Ball Screws uni.edu

F Design calculation and inquiry form….. 56 Designation system.. 58 G SKF Linear Motion Rollers screws, electromechanical cylinders technology and solutions related to precision rolled ball screws. Thanks to our lengthy experience with manufacturing ball screws and continuous product and process devel – opment, SKF provides customers with preci – sion rolled ball screw solutions that

A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw.

ball bearings can handle the loading force from both the axial and radial directions, and by increasing the number of ball bearing sets will improve their loading capacity. For a back to back configuration, there is a large distance between the acting load center

Keywords: Ball screw, Selection of ball screw, Preloading of ball screw, Calculations, Design of recirculating ball screw advantages, Disadvantages, Applications INTRODUCTION Recirculating ball screw consists of screw and nut, the surfaces of which are separated by series of balls. The screw and the nut have approximately semi-circular thread profiles instead of conventional square or

Motion Control & Systems Ballscrews Ballscrews & Accessories Ballscrews consist of a shaft, a nut into which the balls are integrated and the ball recirculation system.

The Ball Screw movement results in virtually no wear, as the rolling-contact design, combined with the use of carefully selected heat-treated materials, results in an …

The screw and nut on a ball screw have matching helical grooves that allow ball bearings to re-circulate in those races, and they are typically semi-circular in shape to accept the spherical ball bearing.

taken to ensure that the ball track is not struck by a sharp edged component or tool, and metallic debris does not enter the ball nut (Fig. 1.1). (2) Select a suitable grade …

5. DESIGN OF NUTS 5.1 Construction of Nut TOSOK Precision ball screws are available in two standard types the internal circulating system using a return guide

DIN 69 051, Part 1 defi nes a ball screw as follows: An assembly comprising a ball screw shaft and a ball nut and which is capable of converting rotary motion into linear motion and vice versa.

Screw design pdf – design pdf A screw thread is defined as a ridge of uniform section in Press and Snap Fit Assembly ball screw design pdf The constant development of new

The ball screw, which can transform the rotation of the servo motor into linear motion of machine tool worktable, tool or other components, or the torque into axial cyclic force, is the most commonly used transmission element in

S99TE08-0206 9. 4. Design and Selection of Ballscrews 4.1 Fundamental Concepts for Selection & Installation (1).

Screw Drive Product Catalogue – Motion Tech

Ball Screw Design Resources. When you need a ball screw, we will walk you through the specification process. In this article, you will find some basic design information, terms explained, and …

Chapter 1 What is a Ball Screw?

Ball Screw Technical Description Construction of Ball

iVL C. Lin S. A. Velinsky B. Ravani Department of Mechanical & Aeronautical Engineering, University of CaliforniaâDavis, Davis, CA 95616 Design of the Ball Screw echanism…

Screw Drive Product Catalogue – Motion Tech

15.2 Design Cautions to Assembling Ball Screw Ball Screw B-1-2.1 Ball Recirculation System A ball recirculation system is categorically most important, as well as the preload system, to classify the structure of ball screw. As shown in Table 2.1, four types of ball recirculation system are used for the NSK ball screws. [Structure] Balls are recirculated by a horseshoe shaped deflector

The Fundamentals of Ball Screws Machine Design

Main Design of ball screw Mathematical Optimization

Features of the Ball Screw With the Ball Screw, balls roll between the screw shaft and the nut to achieve high efficiency. Its required driving torque is only one third of the conventional sliding screw …

Custom Ball Screw Design Beaver Aerospace

NPM Introduction Linear Actuators Nippon Pulse

Main Design of ball screw Mathematical Optimization

F Design calculation and inquiry form….. 56 Designation system.. 58 G SKF Linear Motion Rollers screws, electromechanical cylinders technology and solutions related to precision rolled ball screws. Thanks to our lengthy experience with manufacturing ball screws and continuous product and process devel – opment, SKF provides customers with preci – sion rolled ball screw solutions that

Features of the Ball Screw Driving Torque One Third of the

Power Screws and Ball Screws uni.edu

Modifica on factor for steel treatment (ball screw)fm_i 1 Modifica on factor for steel treatment (ball nut)fm_e 1 Modifica on factor for surface hardness (sta c, ball

Main Design of ball screw [PDF Document]

• Understand principles of operation of ball screws and how they differ from friction-type power screws. • Understand and calculate torque and efficiencies of power screws and ball screws. • Understand and envision how power screws and ball screws can be used in different designs. 2 Power screw A screw and nut to transmit power or motion The axial movement of the nut is used to drive a

Design of high-precision ball screw based on small-ball

Ball Screw Design Resources Dynatect Manufacturing

5. DESIGN OF NUTS nidec-tosok.co.jp

Ball screw is a precision screw mechanism, which is designed for rolling contact that uses steel balls between a screw shaft and a nut to transfer the force and motion for accurate positioning and higher speed in linear movement.

Ball Screws & Accessories pic-design.com

Features of the Ball Screw Driving Torque One Third of the

Chapter 1 What is a Ball Screw?

Staf Ball Screw Technology has the highest commitment to product quality and as a result has made quality the centrepiece of their ball screw design. Staf continuously focuses on improving product reliability, durability, cost competitiveness and customer satisfaction.

Ball Screw Design Resources Dynatect Manufacturing

This paper develops theories for evaluating the efficiency of the ball screw mechanism and additionally, for designing this mechanism. Initially, a quasi-static analysis, which is similar to that of the early work in this area, is employed to evaluate efficiency.

Ball screw Wikipedia

Ball-Screw Design The Advantages of Internal Ball Returns

F Design calculation and inquiry form….. 56 Designation system.. 58 G SKF Linear Motion Rollers screws, electromechanical cylinders technology and solutions related to precision rolled ball screws. Thanks to our lengthy experience with manufacturing ball screws and continuous product and process devel – opment, SKF provides customers with preci – sion rolled ball screw solutions that

Solidworks Design ball screw – YouTube

Ball Screw Design Resources Dynatect Manufacturing

Types of Ball Screws CBM Industries

Motion Control & Systems Ballscrews Ballscrews & Accessories Ballscrews consist of a shaft, a nut into which the balls are integrated and the ball recirculation system.

Aerospace Ball Screws. Steinmeyer

F Design calculation and inquiry form….. 56 Designation system.. 58 G SKF Linear Motion Rollers screws, electromechanical cylinders technology and solutions related to precision rolled ball screws. Thanks to our lengthy experience with manufacturing ball screws and continuous product and process devel – opment, SKF provides customers with preci – sion rolled ball screw solutions that

Aerospace Ball Screws. Steinmeyer

etul attention to design, quality ot materials, heat treatment able and trouble free during the period of expected service s governed by the wear on the contact surfaces, HlWlN’s

Solidworks Design ball screw – YouTube

This paper addresses a design method of ball screws for high-precision feed drives of machine tools. The torque fluctuation of a ball screw influences position deviation, which deteriorates the

5. DESIGN OF NUTS nidec-tosok.co.jp

Main Design of ball screw [PDF Document]

This paper addresses a design method of ball screws for high-precision feed drives of machine tools. The torque fluctuation of a ball screw influences position deviation, which deteriorates the

Ball Screw Technical Description Construction of Ball

Design of high-precision ball screw based on small-ball

15.2 Design Cautions to Assembling Ball Screw Ball Screw B-1-2.1 Ball Recirculation System A ball recirculation system is categorically most important, as well as the preload system, to classify the structure of ball screw. As shown in Table 2.1, four types of ball recirculation system are used for the NSK ball screws. [Structure] Balls are recirculated by a horseshoe shaped deflector

NSK Ball Screws for High-Load Drive

Chapter 1 What is a Ball Screw?

best selection of a ball screw, the designer should specify such cri- tical parameters as the load profile, the linear or rotational speed, the rates of acceleration and deceleration, the cycle rate, the envi-

Chapter 1 What is a Ball Screw?

Main Design of ball screw [PDF Document]

A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw.

Design and Analysis of Lead Screw for Fixture IJMTER

Selection and Installation of HIWIN Ballscrews

Ball Screw Design Considerations Nook Industries

• Motor uses NEMA11 and NEMA17 sizing, which are widely available for ball screw actuators, providing options for user applications. • Captive type actuator’s compact design comes with anti-rotating device installed, with combination of Ball Screw

Development of a new lapping method for ScienceDirect

Design & Selection of HIWIN Ballscrew Ballscrews, also called a ball bearing screws, recirculating ballscrews, etc., consist of a screw spindle and a nut integrated with balls and the balls’ return mechanism, return tubes or return caps. Ballscrews are the most common type of screws used in industrial machinery and precision machines. The primary function of a ballscrew is to convert

Aerospace Ball Screws. Steinmeyer

Ball Screw Design Bearing (Mechanical) Screw

The screw and nut on a ball screw have matching helical grooves that allow ball bearings to re-circulate in those races, and they are typically semi-circular in shape to accept the spherical ball bearing.

(PDF) Design of Hyper Redundant Robot using Ball screw

Main Design of ball screw [PDF Document]

NPM Introduction Linear Actuators Nippon Pulse

• Understand principles of operation of ball screws and how they differ from friction-type power screws. • Understand and calculate torque and efficiencies of power screws and ball screws. • Understand and envision how power screws and ball screws can be used in different designs. 2 Power screw A screw and nut to transmit power or motion The axial movement of the nut is used to drive a

Features of the Ball Screw Driving Torque One Third of the

Screw Drive Product Catalogue – Motion Tech

Ball Screw PDF Bearing (Mechanical) scribd.com

Design & Selection of HIWIN Ballscrew Ballscrews, also called a ball bearing screws, recirculating ballscrews, etc., consist of a screw spindle and a nut integrated with balls and the balls’ return mechanism, return tubes or return caps. Ballscrews are the most common type of screws used in industrial machinery and precision machines. The primary function of a ballscrew is to convert

Development of a new lapping method for ScienceDirect

design of ball screw for optimum efficiency-1 Download as PDF, TXT or read online from Scribd

Ball Screw Technical Description Construction of Ball

taken to ensure that the ball track is not struck by a sharp edged component or tool, and metallic debris does not enter the ball nut (Fig. 1.1). (2) Select a suitable grade …

Power Screws and Ball Screws uni.edu

design of ball screw for optimum efficiency-1 Download as PDF, TXT or read online from Scribd

Ball Screws – BT Precision

Ball Screw PDF Bearing (Mechanical) scribd.com

RECIRCULATING BALL SCREW ijerst

Ball screw is a precision screw mechanism, which is designed for rolling contact that uses steel balls between a screw shaft and a nut to transfer the force and motion for accurate positioning and higher speed in linear movement.

Screw Drive Product Catalogue – Motion Tech

This paper addresses a design method of ball screws for high-precision feed drives of machine tools. The torque fluctuation of a ball screw influences position deviation, which deteriorates the

BALL SCREWS PLANETARY AND INVERTED ROLLER SCREWS

Chapter 1 What is a Ball Screw?

A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw.

Ball Screw Technical Description Construction of Ball

Features of the Ball Screw Driving Torque One Third of the

Main Design of ball screw Mathematical Optimization

best selection of a ball screw, the designer should specify such cri- tical parameters as the load profile, the linear or rotational speed, the rates of acceleration and deceleration, the cycle rate, the envi-

NSK Ball Screws for High-Load Drive

• Motor uses NEMA11 and NEMA17 sizing, which are widely available for ball screw actuators, providing options for user applications. • Captive type actuator’s compact design comes with anti-rotating device installed, with combination of Ball Screw

Ball Screw Design Considerations Nook Industries

design of ball screw for optimum efficiency-1 Download as PDF, TXT or read online from Scribd

Ball Screw Calcula on MESYS AG

Screw Drive Product Catalogue – Motion Tech

• Understand principles of operation of ball screws and how they differ from friction-type power screws. • Understand and calculate torque and efficiencies of power screws and ball screws. • Understand and envision how power screws and ball screws can be used in different designs. 2 Power screw A screw and nut to transmit power or motion The axial movement of the nut is used to drive a

Ball Screw Design Considerations Nook Industries

The screw and nut on a ball screw have matching helical grooves that allow ball bearings to re-circulate in those races, and they are typically semi-circular in shape to accept the spherical ball bearing.

THE ENGINEER’S GUIDE LEAD SCREWS VS. BALL SCREWS

NSK ball screws for high load drive have increased load capacity by maximizing the diameter of balls in relation to the lead, increasing the number of valid load balls and optimizing the shape of ball groove for a design that can withstand high load.

Screw Drive Product Catalogue – Motion Tech

One challenge in ball-screw design is ball recirculation. Historically, the most common designs used tubes that jutted outside the nut and provided a return path back to the beginning of the ball

Screw Drive Product Catalogue – Motion Tech

This paper addresses a design method of ball screws for high-precision feed drives of machine tools. The torque fluctuation of a ball screw influences position deviation, which deteriorates the

NSK Standard Ball Screws Compact FA Series

Ball Screw Design Considerations Nook Industries

Design of high-precision ball screw based on small-ball

Ball Screw Technical Information.pdf pdf 69.74 KB Ball Screws Our selection of ball screws in alloy or stainless should help satisfy any high load, high efficiency applications.

Design of high-precision ball screw based on small-ball

of the largest ball screw factories, utilizing the latest state of the art equipment, combined with over 50 years of experience and a dedicated design and test facility for aerospace product, guarantees

5. DESIGN OF NUTS nidec-tosok.co.jp

ball bearings can handle the loading force from both the axial and radial directions, and by increasing the number of ball bearing sets will improve their loading capacity. For a back to back configuration, there is a large distance between the acting load center

Solidworks Design ball screw – YouTube

Aerospace Ball Screws. Steinmeyer

In this paper, new approach that using ball screw mechanism is provided. The designed approach is the novel combination of serial base and parallel structured actuators. The proposed robot has 12

Ball Screws & Accessories pic-design.com

Design of the Ball Screw Mechanism for Optimal Efficiency

The screw and nut on a ball screw have matching helical grooves that allow ball bearings to re-circulate in those races, and they are typically semi-circular in shape to accept the spherical ball bearing.

NSK Ball Screws for High-Load Drive

Ball Screw Design Resources. When you need a ball screw, we will walk you through the specification process. In this article, you will find some basic design information, terms explained, and …

Ball-Screw Design The Advantages of Internal Ball Returns

S99TE08-0206 9. 4. Design and Selection of Ballscrews 4.1 Fundamental Concepts for Selection & Installation (1).

Design of the Ball Screw Mechanism for Optimal Efficiency

• Understand principles of operation of ball screws and how they differ from friction-type power screws. • Understand and calculate torque and efficiencies of power screws and ball screws. • Understand and envision how power screws and ball screws can be used in different designs. 2 Power screw A screw and nut to transmit power or motion The axial movement of the nut is used to drive a

Design of the Ball Screw Mechanism for Optimal Efficiency

(PDF) Design of Hyper Redundant Robot using Ball screw

Types of Ball Screws CBM Industries

Ball Screw Design Resources. When you need a ball screw, we will walk you through the specification process. In this article, you will find some basic design information, terms explained, and …

Ball-Screw Design The Advantages of Internal Ball Returns

Design and Analysis of Lead Screw for Fixture IJMTER

Main Design of ball screw Mathematical Optimization

Ball selection is a low-cost method that involves using preselected, oversized ball bearings to create four points of contact between the nut and screw. This permits heavier loads, but friction

NPM Introduction Linear Actuators Nippon Pulse

Many parameters must be considered when designing or selecting a ball screw assembly. Operating load, speed, accuracy, environment, and power requirements all play major roles in the design criteria.

Selection and Installation of HIWIN Ballscrews

Custom Ball Screw Design . Designing ball screws is sometimes as much art as science. With eyes trained on the new and innovative, while maintaining a healthy respect for what has been proven, our engineers work with the latest design tools to create optimum ball screw and actuator configurations for …

5. DESIGN OF NUTS nidec-tosok.co.jp

etul attention to design, quality ot materials, heat treatment able and trouble free during the period of expected service s governed by the wear on the contact surfaces, HlWlN’s

THE ENGINEER’S GUIDE LEAD SCREWS VS. BALL SCREWS

NSK Standard Ball Screws Compact FA Series

NSK Standard Ball Screws: Compact FA Series Compact FA Series ball screws incorporate NSK’s ball recirculation system and offer quiet, high-speed performance. In order to respond quickly to a wide range of needs, NSK offers four-week delivery on common sizes.

Development of a new lapping method for ScienceDirect

The ball screw, which can transform the rotation of the servo motor into linear motion of machine tool worktable, tool or other components, or the torque into axial cyclic force, is the most commonly used transmission element in

5. DESIGN OF NUTS nidec-tosok.co.jp

NPM Introduction Linear Actuators Nippon Pulse

Linear Modules, a motor driven optimized modulized compound unit, is composed of ballscrews and linear guideways. The specialty of this compound unit is widely applied to the precision machinery, semiconductor equipment and other equipment with accurate positioning requirement.

RECIRCULATING BALL SCREW ijerst

• Understand principles of operation of ball screws and how they differ from friction-type power screws. • Understand and calculate torque and efficiencies of power screws and ball screws. • Understand and envision how power screws and ball screws can be used in different designs. 2 Power screw A screw and nut to transmit power or motion The axial movement of the nut is used to drive a

Screw Drive Product Catalogue – Motion Tech

Ball Screws – BT Precision

Design of Ball Screw Mechanism for Retro Fit of External

• Motor uses NEMA11 and NEMA17 sizing, which are widely available for ball screw actuators, providing options for user applications. • Captive type actuator’s compact design comes with anti-rotating device installed, with combination of Ball Screw

Custom Ball Screw Design Beaver Aerospace

iVL C. Lin S. A. Velinsky B. Ravani Department of Mechanical & Aeronautical Engineering, University of CaliforniaâDavis, Davis, CA 95616 Design of the Ball Screw echanism…

RECIRCULATING BALL SCREW ijerst

BALL SCREWS PLANETARY AND INVERTED ROLLER SCREWS

Ball Screw PDF Bearing (Mechanical) scribd.com

Ball Screw Design Resources. When you need a ball screw, we will walk you through the specification process. In this article, you will find some basic design information, terms explained, and …

Ball Screws – BT Precision

Ball-Screw Design The Advantages of Internal Ball Returns

• Understand principles of operation of ball screws and how they differ from friction-type power screws. • Understand and calculate torque and efficiencies of power screws and ball screws. • Understand and envision how power screws and ball screws can be used in different designs. 2 Power screw A screw and nut to transmit power or motion The axial movement of the nut is used to drive a

Types of Ball Screws CBM Industries

Custom Ball Screw Design Beaver Aerospace

Power Screws and Ball Screws uni.edu

Keywords: Ball screw, Selection of ball screw, Preloading of ball screw, Calculations, Design of recirculating ball screw advantages, Disadvantages, Applications INTRODUCTION Recirculating ball screw consists of screw and nut, the surfaces of which are separated by series of balls. The screw and the nut have approximately semi-circular thread profiles instead of conventional square or

Main Design of ball screw Mathematical Optimization

A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw.

Power Screws and Ball Screws uni.edu

Ball Screws – BT Precision

In this paper, new approach that using ball screw mechanism is provided. The designed approach is the novel combination of serial base and parallel structured actuators. The proposed robot has 12

Ball Screw PDF Bearing (Mechanical) scribd.com

The screw and nut on a ball screw have matching helical grooves that allow ball bearings to re-circulate in those races, and they are typically semi-circular in shape to accept the spherical ball bearing.

5. DESIGN OF NUTS nidec-tosok.co.jp

Staf Ball Screw Technology has the highest commitment to product quality and as a result has made quality the centrepiece of their ball screw design. Staf continuously focuses on improving product reliability, durability, cost competitiveness and customer satisfaction.

Custom Ball Screw Design Beaver Aerospace

Main Design of ball screw [PDF Document]

The Fundamentals of Ball Screws Machine Design

design and manufacturing, and the company eventually succeeded in launching the first ball screw type automobile steering gears in Japan in 1958. Although the main application target for the precision ball screws was NC machine tools, the first

Screw Drive Product Catalogue – Motion Tech

THE ENGINEER’S GUIDE LEAD SCREWS VS. BALL SCREWS

Design and Analysis of Lead Screw for Fixture IJMTER

5. DESIGN OF NUTS 5.1 Construction of Nut TOSOK Precision ball screws are available in two standard types the internal circulating system using a return guide

Features of the Ball Screw Driving Torque One Third of the

RECIRCULATING BALL SCREW ijerst

Design of high-precision ball screw based on small-ball

of the largest ball screw factories, utilizing the latest state of the art equipment, combined with over 50 years of experience and a dedicated design and test facility for aerospace product, guarantees

Ball screw Wikipedia

Ball Screw Design Resources. When you need a ball screw, we will walk you through the specification process. In this article, you will find some basic design information, terms explained, and …

Ball-Screw Design The Advantages of Internal Ball Returns

Ball Screw Design Bearing (Mechanical) Screw

Ball Screw Design Considerations Mounting and Pinning of Ball Nut Flange. If a flange is used, it must be permanently fixed to the nut. Since mounting methods usually require the disassembly of the ball nut from the screw, it is best to order the nut and flange factory assembled.

Ball Screw Technical Description Construction of Ball

Aerospace Ball Screws. Steinmeyer

12 4. DESIGN OF SCREW SHAFTS 4.6 Hints on Designing a Screw Shaft (1) Mounting When mounting a ball screw, it is not advisable to select such a construction that the screw shaft has to be discon-

(PDF) Design of Hyper Redundant Robot using Ball screw

Ball Screw PDF Bearing (Mechanical) scribd.com

design of ball screw for optimum efficiency-1 Download as PDF, TXT or read online from Scribd

5. DESIGN OF NUTS nidec-tosok.co.jp

Ball Screw Design Bearing (Mechanical) Screw

Ball Screw Design Considerations Mounting and Pinning of Ball Nut Flange. If a flange is used, it must be permanently fixed to the nut. Since mounting methods usually require the disassembly of the ball nut from the screw, it is best to order the nut and flange factory assembled.

Solidworks Design ball screw – YouTube

Power Screws and Ball Screws uni.edu

One challenge in ball-screw design is ball recirculation. Historically, the most common designs used tubes that jutted outside the nut and provided a return path back to the beginning of the ball

Aerospace Ball Screws. Steinmeyer

F Design calculation and inquiry form….. 56 Designation system.. 58 G SKF Linear Motion Rollers screws, electromechanical cylinders technology and solutions related to precision rolled ball screws. Thanks to our lengthy experience with manufacturing ball screws and continuous product and process devel – opment, SKF provides customers with preci – sion rolled ball screw solutions that

Ball Screw Design Considerations Nook Industries

Ball-Screw Design The Advantages of Internal Ball Returns

A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw.

NSK Ball Screws for High-Load Drive

Ball Screw Design Considerations Nook Industries

Screw Drive Product Catalogue – Motion Tech

ball bearings can handle the loading force from both the axial and radial directions, and by increasing the number of ball bearing sets will improve their loading capacity. For a back to back configuration, there is a large distance between the acting load center

Custom Ball Screw Design Beaver Aerospace

etul attention to design, quality ot materials, heat treatment able and trouble free during the period of expected service s governed by the wear on the contact surfaces, HlWlN’s

Design of Ball Screw Mechanism for Retro Fit of External

THE ENGINEER’S GUIDE LEAD SCREWS VS. BALL SCREWS

Motion Control & Systems Ballscrews Ballscrews & Accessories Ballscrews consist of a shaft, a nut into which the balls are integrated and the ball recirculation system.

Power Screws and Ball Screws uni.edu

Main Design of ball screw Mathematical Optimization

(PDF) Design of Hyper Redundant Robot using Ball screw

F Design calculation and inquiry form….. 56 Designation system.. 58 G SKF Linear Motion Rollers screws, electromechanical cylinders technology and solutions related to precision rolled ball screws. Thanks to our lengthy experience with manufacturing ball screws and continuous product and process devel – opment, SKF provides customers with preci – sion rolled ball screw solutions that

Features of the Ball Screw Driving Torque One Third of the

Solidworks Design ball screw – YouTube

ball bearings can handle the loading force from both the axial and radial directions, and by increasing the number of ball bearing sets will improve their loading capacity. For a back to back configuration, there is a large distance between the acting load center

Types of Ball Screws CBM Industries

Ball Screw Technical Description Construction of Ball

One challenge in ball-screw design is ball recirculation. Historically, the most common designs used tubes that jutted outside the nut and provided a return path back to the beginning of the ball …

Solidworks Design ball screw – YouTube

Features of the Ball Screw With the Ball Screw, balls roll between the screw shaft and the nut to achieve high efficiency. Its required driving torque is only one third of the conventional sliding screw …

Design of the Ball Screw Mechanism for Optimal Efficiency

Ball Screw PDF Bearing (Mechanical) scribd.com

Ball screws, also called a ball bearing screws, recirculating balls screws, etc., consist of a screw spindle and a nut integrated with balls and the balls return mechanism, return tubes or return caps.

Main Design of ball screw Mathematical Optimization

Solidworks Design ball screw – YouTube