High energy ball milling pdf

The typical mill used for these purposes has been the high energy ball mill such as tumbler ball mills, vibratory mills, planetary mills, and attritor mills (Szegvari attritor) etc. A detailed description of the different mills available for MM can be found in Suryanarayana handbook [25]; however we have discussed a brief description regarding high energy ball mills.

High Energy Ball Mill The Emax is an entirely new type of ball mill which was specifically designed for high energy milling. The impressive speed of 2,000 min-1,

J. Liu et al. /Science of Sintering, 48 (2016) 353-362 _____ 354 milled mixtures of Mg(OH)2 and Al(OH)3 after over 15 min of calcination at 900 °C.

X-ray diffraction analysis of tin metal powder produced by high energy ball milling L. Manzato 1, Q. H. F. Rebelo 2, D.M. Trichês 2, S. M. Souza 2, M. F. de Oliveira 3

Evidence for self-sustained MoSi2 formation during room-temperature high-energy ball milling of elemental powders E. Ma,a) J. Pagan, G. Cranford, and M. Atzmon

MIXER/MILL ® HIGH ENERGY BALL MILL. MIXER/MILL ® Sound Insulation Membrane Control Panel Forced Air Cooling Fan Lid Latch Safety (Interlock) BEFORE AFTER PHARMACEUTICALS SUPER ALLOY GRANITE GLASS BEFORE AFTER Timer range to 100 minutes. Optional chip* is available to extend timer range to 175 hours (10,500 minutes). Steel housing and rugged construction ensure a …

3. Results and discussion After the low energy ball milling (milling A), the agglomerates exhibit a granular microstructure composed of almost pure elemental particles (Fig 1.

294 Journal of Ceramic Science and Technology —A.E. Hannora Vol. 5, No. 4 The purpose of the present study is to produce HA/alu-mina composite by means of the vibratory ball milling

PDF On Aug 19, 2015, Ahmed E. Hannora and others published Synthesis of lead-borate glasses using high energy ball milling (attritor)

Cadmium Sulfide (CdS) preparation by High-Energy Ball Milling I. Estrada-Guel1, C.D. Gómez-Esparza1, L. González-Rodelas2 and R. Martínez-Sánchez1

Preparation of Micrometer- to Sub-micrometer-Sized Nanostructured Silica Particles Using High-Energy Ball Milling J. Eric Hampsey, Claudio L. De Castro, …

The E max is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time.

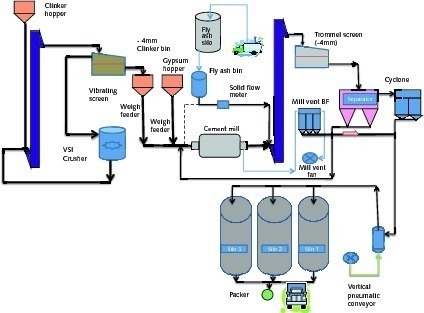

22/02/2018 · Best Price High Output ball mill design pdf manufacturer .. Pakistan ball grinding mill for cement industry new design stone ball mill for sale . mineral processing ball mill machine energy saving tubular ball mill. Quotation More. Stone Powder Machine. Stone Powder Machine, Wholesale Various High Quality Stone Powder Machine Products from . powder grinder machine ball mill stone …

Effects of High-Energy Ball Milling on High Entropy Alloys

Acceleration of Hydrogen Desorption from MgH2 by High

result of the capacity of high-energy ball milling to induce selenium amorphisation because of its special molecular structure that consists of helical molecular chains that are bonded together by weak van der Waals forces [22].

2015; 18(5) Synthesis of SnSb 955 2 Te 4 Microplatelets by High-Energy Ball Milling 4. Conclusion SnSb 2 Te 4-based microplatelets were successfully synthesized via mechanochemical activation using

The Emax is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within. The unique combination of high friction and impact results in extremely fine particles within.

Effect of process variables on the synthesis of MgB 2 by high energy ball mill 971 pressing. MA was performed in a planetary ball mill with using high quality

Taguchi’s method was applied to investigate the effect of the main HEBM parameters: milling time (MT), ball to powder weight ratio (BPWR) and milling speed (MS) on the dissolved AlN fraction in TiN.

In this investigation, the chemical and microstructural characteristics of nanostructured AlFe intermetallic produced by high-energy ball milling have been explored.

High energy ball milling in high purity argon of alloys of NdFeB both with and without additions of Co and Zr, combined with suitable heat treatment, has been used to produce magnetic powders with coercivities up to 960 kA m −1 (12 kOe).

customer magazine issue 39 planetary ball mill pm 100 mixer mill cryomill mm 400 high energy ball mills grinding and particle sizing on a nanoscale

istry, the term high-energy milling is frequently used in order to stress the character of applied milling equipments (mills) [Boldyrev 1983; Bal´aˇz 2000]. The chapter is intended as an introduction to the topic of high-energy milling and

169 Abd-Elmoneim M. Shamah et al.: Structural Analysis of PbO-B2O3-ZnO Glasses by High Energy Ball Milling (Attritor) glasses because it enhances the resistance against

Advantages And Disadvantages Of Ball Mill. vertical ball mill working principle pdf offers 109 advantages and disadvantages of ball mill products. . What Is Ball Mill And Its Working Principle? The usage of ball mill and its technical data Ball mill is widely used for …

high-energy ball milling Chengduo Wang, Yanwei Ma, Xianping Zhang et al.-Effective carbon incorporation in MgB2 by combining mechanical milling and the glycerintreatment of boron powder Byung-Hyuk Jun, Yi-Jeong Kim, Kai Sin Tan et al.-Recent citations The reduction of optimal heat treatment temperature and critical current density enhancement of ex situ processed MgB 2 tapes using ball …

Acceleration of Hydrogen Desorption from MgH2 by High-Energy Ball-Milling with Al2O3, TiO2, Cr2O3, and ZrO2 for Exremely Short Time Manshi Ohyanagi1, Natsuki Yamasaki1, Hiroya Tabuchi1, and Zuhair A. Munir2

High energy ball milling: Mechanochemical processing of nanopowders reviews the latest techniques in mechanochemistry and how they can be applied to the synthesis and processing of various high …

In order to develop a high-strength aluminum alloy, alumina dispersion strengthened aluminum alloy was prepared by high energy ball milling on 2024 aluminum alloy powder in ethanol. The microstructure, particle size and distribution of the Al2O3 particles in the alloy were analyzed by FE-SEM; the mechanical properties were investigated. Results

Optimization of the high energy ball-milling: Modeling and parametric study Hamid Ghayoura, Majid Abdellahia,⁎, Maryam Bahmanpourb a Advanced Materials Research Center, Faculty of Materials Engineering, Najafabad Branch, Islamic Azad University, Najafabad, Iran

High Energy Ball Milling. In discussions on high energy ball milling, the more generic term “ball mills” is often used in place of the terms “stirred ball mills” or “Attritors,” but the differences between the types of mills are quite distinct.

mechanical alloying using high energy ball mill. Ball to powder ratio, milling medium, and speed of ball mill Ball to powder ratio, milling medium, and speed of ball mill are important parameters which influence effectiveness of milling process.

In high-energy ball milling, plastic deformation, cold-welding and fracture are predominant factors, in which the deformation leads to a change in particle shape, cold -welding leads to an increase in particle size and fracture leads to decrease in particle sizeresulting in the formation of fine dispersed

Milling conditions High-Energy Ball Milling Planetary mill Retsch P100 Stainless steel vial 250ml Ball / powder ratio 5:1 Ball (stainless steel) size 10 mm

high energy ball milling and SPS. Fig. 4. SEM images of spark plasma sintered V-V2C in-situ nanocomposites at a) 1150 °C b) 1250 °C c) 1350 °C, EDS area scan analysis of samples sintered at d) 1150 °C e) 1250 °C, and f) 1350 °C.

JOURNAL OF MATERIALS SCIENCE36(2001)5105– 5113 Sub-micron sized Al 2TiO 5 powders prepared by high-energy ball milling R. URIBE, C. BAUD´IN Instituto de Cer´amica y Vidrio (CSIC), Arganda del Rey, Madrid, Spain 28500

HIGH ENERGY BALL MILLING – A PROMISING ROUTE FOR PRODUCTION OF TAILORED THERMAL SPRAY CONSUMABLES A. WANK, B. WIELAGE Institute of Composite Materials, Chemnitz University of Technology, Chemnitz, Germany

high energy ball milling in malaysia companypens.co.za

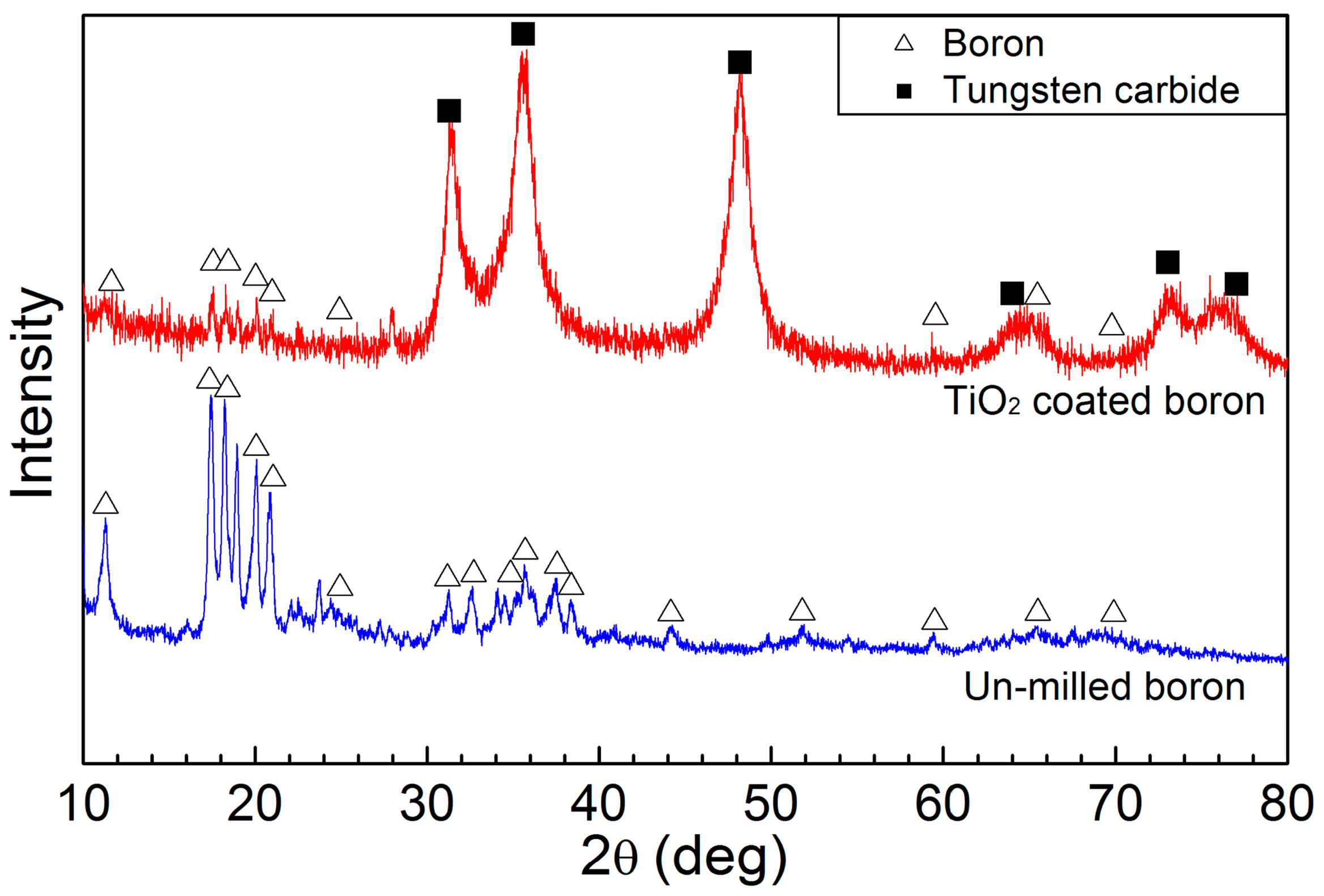

using a high energy ball milling for 30 hours. The milled specimen is analyzed with an X-Ray Diffractometer and analyzed The milled specimen is analyzed with an X-Ray Diffractometer and analyzed qualitatively and quantitatively using Rietveld method developed by Fuji Izumi.

through high energy ball-milling was investigated in details. The graphene with carboxylated edge was The graphene with carboxylated edge was successfully fabricated via high energy ball-milling method in the presence of dry ice to create a high

In high-energy ball milling, plastic deformation, cold-welding and fracture predominantly contribute to bring a change in size, shape and microenvironment of nanoparticles.

ball mill energy conservation pdf . Energy Efficiency and Carbon Dioxide Emissions Reduction . September 1999. This work was supported by the Assistant Secretary of Energy Efficiency and Renewable Energy and estimated energy savings, carbon dioxide savings, investment costs, and operation and .. the cement (gypsum and anhydrite) can be done in

High-energy ball milling Mechanochemical processing of nanopowders Editedby MalgorzataSopicka-Lizer CRCPress BocaRaton Boston NewYork Washington,DC WOODHEAD PUBLISHING LIMITED

268 industrial processes and has an increasing importance in engineering materials, being a process that can occur either continuously or batch wiseThis technique cause changes .

ResearchArticle Effects of Processing Parameters on the Synthesis of (K 0.5 Na 0.5)NbO 3 Nanopowders by Reactive High-Energy Ball Milling Method NguyenDucVan

A Green Method for Graphite Exfoliation Using High-Energy Ball Milling. I. Estrada-Guel1,2, F.C. Robles-Hernandez2, J.M. Mendoza-Duarte1, R. Pérez-Bustamante1 and R.

How to Cite. Azhdar, B., Stenberg, B. and Kari, L. (2008), Polymer–nanofiller prepared by high-energy ball milling and high velocity cold compaction. – dragon ball xenoverse guide book Table I-2: devices used to perform Mechanical Alloying, High Energy Milling and Reactive Milling Compared to the (vertical) attritors (4.5-5.1 m/s) and to the planetary ball mill (5 m/s), the Simoloyer ® …

materials Article The Structure and Mechanical Properties of High-Strength Bulk Ultrafine-Grained Cobalt Prepared Using High-Energy Ball Milling in

In this study, the heterogeneous Fenton oxidation of ciprofloxacin (CIP) in an aqueous solution was examined over the nano-sized magnetite (FeO) as a catalyst supplied through high-energy planetary ball milling process.

High Energy Ball Milling of YAG Powders: Sintering Properties and Microstructural Evaluation 331 TheformationofnewY-Aphases(suchasYAG,YAP, YAM

C powders by high-energy ball milling and further heat treatment. The milling process was carried out in a planetary ball mill. Following the milling process, powder samples were heat-treated at

Characterization of α-Fe2O3 Nanoparticles Produced by High Energy Ball Milling O. M. LEMINE*1, A.ALYAMANI2, M. SAJIEDDINE3 AND M.BOUOUDINA4 1 Physics Department, College of Sciences, Imam University, Riyadh, Saudi Arabia.

Preparation of Bi. 4. Ti. 3. O. 12 (BIT) Ceramics via a High-Energy Ball Milling Process Doped with Multi-Walled Carbon Nanotubes (MWNTs) 550 . Bi. 2. O. 3. and TiO

EUROPHYSICS LETTERS 1 April 1998 Europhys. Lett., 42 (1), pp. 91-96 (1998) Magnetic properties of Ni nanoparticles dispersed in silica prepared by high-energy ball milling

Mechanical Synthesis of Iron and Nickel Solid Solution by High Energy Ball Milling for Packaging Iman Farahbakhsh, Afshin Farahbakhsh Department of Engineering, Quchan Branch, Islamic Azad University, Quchan, Iran Received: October 29, 2014 Accepted: December 31, 2014 ABSTRACT Mechanical alloying (MA) is a solid-state powder processing technique involving repeated cold …

High-Energy Ball Mill Processing Edval G. Araújo, Ricardo M. Leal Neto, Marina F. Pillis, Francisco Ambrózio Filho Instituto de Pesquisas Energéticas e Nucleares IPEN-CNEN-SP,

Supercond. Sci. Technol. 25 (2012) 035018 C Wang et al microstructure and non-metallic (mainly oxygen) content of the low purity boron powders with the same purity have an

High Energy and Reactive Milling is performed by the same processing principle where the variation is in general based on the target of processing, the transformation effect of …

• The Bond ball mill work index (BWI) trends strongly upwards from north to south in the P zone, is relatively consistent in the O zone, is much harder in the south H …

High Energy Ball Milling Manufacturer: Retsch Model: EMax Description The Emax is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time. Due to the special grinding jar geometry, the sample is thoroughly mixed which results in a narrow particle size distribution. Some

Processing and Applicationof Ceramics 10 [3] (2016)143–152 DOI: 10.2298/PAC1603143M Effect of high-energy ball milling on the electrical properties of

Effect of high-energy ball milling on the electrical

High-energy ball milling is a type of mechanical grinding of materials. This process can be conducted in a dry (without solvents) or wet (with solvents) fashion. Laboratory-scale ball milling (5−100 mL scale) is a batch process, whereas industrial ball mills can be operated in a continuous mode, thus offering a very high synthesis throughput. The milling occurs due to mechanical friction

Characterization of α-Fe2O3 Nanoparticles Produced by High

High Energy Ball Milling of YAG Powders Sintering

Preparation of Micrometer to SubmicrometerSized

Influence of Parameters of High-energy Ball Milling on the

Synthesis of SnSb Te Microplatelets by High-energy Ball

Emax High Energy Ball Mill – Retsch

High Energy Ball Milling NTU MSE

2018 nfhs baseball rule book pdf – ACHIEVEMENT OF HIGH ENERGY EFFICIENCY IN GRINDING MILLS

Effect of high-energy ball milling time on superconducting

Optimization of High Energy Ball Milling Parameters for

Polymer–nanofiller prepared by high-energy ball milling

Synthesis and characterization of shape memory Nano alloy

Influence of the milling parameters on the mechanical work

Cadmium Sulfide (CdS) preparation by High-Energy Ball Milling I. Estrada-Guel1, C.D. Gómez-Esparza1, L. González-Rodelas2 and R. Martínez-Sánchez1

HIGH ENERGY BALL MILLING – A PROMISING ROUTE FOR PRODUCTION OF TAILORED THERMAL SPRAY CONSUMABLES A. WANK, B. WIELAGE Institute of Composite Materials, Chemnitz University of Technology, Chemnitz, Germany

mechanical alloying using high energy ball mill. Ball to powder ratio, milling medium, and speed of ball mill Ball to powder ratio, milling medium, and speed of ball mill are important parameters which influence effectiveness of milling process.

Processing and Applicationof Ceramics 10 [3] (2016)143–152 DOI: 10.2298/PAC1603143M Effect of high-energy ball milling on the electrical properties of

A Green Method for Graphite Exfoliation Using High-Energy Ball Milling. I. Estrada-Guel1,2, F.C. Robles-Hernandez2, J.M. Mendoza-Duarte1, R. Pérez-Bustamante1 and R.

High-energy ball milling is a type of mechanical grinding of materials. This process can be conducted in a dry (without solvents) or wet (with solvents) fashion. Laboratory-scale ball milling (5−100 mL scale) is a batch process, whereas industrial ball mills can be operated in a continuous mode, thus offering a very high synthesis throughput. The milling occurs due to mechanical friction

High Energy Ball Mill The Emax is an entirely new type of ball mill which was specifically designed for high energy milling. The impressive speed of 2,000 min-1,

materials Article The Structure and Mechanical Properties of High-Strength Bulk Ultrafine-Grained Cobalt Prepared Using High-Energy Ball Milling in

• The Bond ball mill work index (BWI) trends strongly upwards from north to south in the P zone, is relatively consistent in the O zone, is much harder in the south H …

C powders by high-energy ball milling and further heat treatment. The milling process was carried out in a planetary ball mill. Following the milling process, powder samples were heat-treated at

The Emax is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within. The unique combination of high friction and impact results in extremely fine particles within.

High Energy Ball Milling. In discussions on high energy ball milling, the more generic term “ball mills” is often used in place of the terms “stirred ball mills” or “Attritors,” but the differences between the types of mills are quite distinct.

Structural Analysis of PbO-B OZnO Glasses by High Energy

The Structure and Mechanical Properties of High-Strength

How to Cite. Azhdar, B., Stenberg, B. and Kari, L. (2008), Polymer–nanofiller prepared by high-energy ball milling and high velocity cold compaction.

using a high energy ball milling for 30 hours. The milled specimen is analyzed with an X-Ray Diffractometer and analyzed The milled specimen is analyzed with an X-Ray Diffractometer and analyzed qualitatively and quantitatively using Rietveld method developed by Fuji Izumi.

Effect of process variables on the synthesis of MgB 2 by high energy ball mill 971 pressing. MA was performed in a planetary ball mill with using high quality

Acceleration of Hydrogen Desorption from MgH2 by High-Energy Ball-Milling with Al2O3, TiO2, Cr2O3, and ZrO2 for Exremely Short Time Manshi Ohyanagi1, Natsuki Yamasaki1, Hiroya Tabuchi1, and Zuhair A. Munir2

High-Energy Ball Mill Processing Edval G. Araújo, Ricardo M. Leal Neto, Marina F. Pillis, Francisco Ambrózio Filho Instituto de Pesquisas Energéticas e Nucleares IPEN-CNEN-SP,

22/02/2018 · Best Price High Output ball mill design pdf manufacturer .. Pakistan ball grinding mill for cement industry new design stone ball mill for sale . mineral processing ball mill machine energy saving tubular ball mill. Quotation More. Stone Powder Machine. Stone Powder Machine, Wholesale Various High Quality Stone Powder Machine Products from . powder grinder machine ball mill stone …

JOURNAL OF MATERIALS SCIENCE36(2001)5105– 5113 Sub-micron sized Al 2TiO 5 powders prepared by high-energy ball milling R. URIBE, C. BAUD´IN Instituto de Cer´amica y Vidrio (CSIC), Arganda del Rey, Madrid, Spain 28500

The typical mill used for these purposes has been the high energy ball mill such as tumbler ball mills, vibratory mills, planetary mills, and attritor mills (Szegvari attritor) etc. A detailed description of the different mills available for MM can be found in Suryanarayana handbook [25]; however we have discussed a brief description regarding high energy ball mills.

High energy ball milling: Mechanochemical processing of nanopowders reviews the latest techniques in mechanochemistry and how they can be applied to the synthesis and processing of various high …

In high-energy ball milling, plastic deformation, cold-welding and fracture are predominant factors, in which the deformation leads to a change in particle shape, cold -welding leads to an increase in particle size and fracture leads to decrease in particle sizeresulting in the formation of fine dispersed

268 industrial processes and has an increasing importance in engineering materials, being a process that can occur either continuously or batch wiseThis technique cause changes .

High Energy Ball Mill The Emax is an entirely new type of ball mill which was specifically designed for high energy milling. The impressive speed of 2,000 min-1,

mechanical alloying using high energy ball mill. Ball to powder ratio, milling medium, and speed of ball mill Ball to powder ratio, milling medium, and speed of ball mill are important parameters which influence effectiveness of milling process.

high energy ball milling in malaysia companypens.co.za

Synthesis of AlFe Intermetallic Nanoparticles by High

Preparation of Micrometer- to Sub-micrometer-Sized Nanostructured Silica Particles Using High-Energy Ball Milling J. Eric Hampsey, Claudio L. De Castro, …

High Energy Ball Milling of YAG Powders: Sintering Properties and Microstructural Evaluation 331 TheformationofnewY-Aphases(suchasYAG,YAP, YAM

High-energy ball milling is a type of mechanical grinding of materials. This process can be conducted in a dry (without solvents) or wet (with solvents) fashion. Laboratory-scale ball milling (5−100 mL scale) is a batch process, whereas industrial ball mills can be operated in a continuous mode, thus offering a very high synthesis throughput. The milling occurs due to mechanical friction

High energy ball milling: Mechanochemical processing of nanopowders reviews the latest techniques in mechanochemistry and how they can be applied to the synthesis and processing of various high …

Cadmium Sulfide (CdS) preparation by High-Energy Ball Milling I. Estrada-Guel1, C.D. Gómez-Esparza1, L. González-Rodelas2 and R. Martínez-Sánchez1

using a high energy ball milling for 30 hours. The milled specimen is analyzed with an X-Ray Diffractometer and analyzed The milled specimen is analyzed with an X-Ray Diffractometer and analyzed qualitatively and quantitatively using Rietveld method developed by Fuji Izumi.

In this investigation, the chemical and microstructural characteristics of nanostructured AlFe intermetallic produced by high-energy ball milling have been explored.

High energy ball milling in high purity argon of alloys of NdFeB both with and without additions of Co and Zr, combined with suitable heat treatment, has been used to produce magnetic powders with coercivities up to 960 kA m −1 (12 kOe).

A Green Method for Graphite Exfoliation Using High-Energy Ball Milling. I. Estrada-Guel1,2, F.C. Robles-Hernandez2, J.M. Mendoza-Duarte1, R. Pérez-Bustamante1 and R.

through high energy ball-milling was investigated in details. The graphene with carboxylated edge was The graphene with carboxylated edge was successfully fabricated via high energy ball-milling method in the presence of dry ice to create a high

Supercond. Sci. Technol. 25 (2012) 035018 C Wang et al microstructure and non-metallic (mainly oxygen) content of the low purity boron powders with the same purity have an

169 Abd-Elmoneim M. Shamah et al.: Structural Analysis of PbO-B2O3-ZnO Glasses by High Energy Ball Milling (Attritor) glasses because it enhances the resistance against

PDF On Aug 19, 2015, Ahmed E. Hannora and others published Synthesis of lead-borate glasses using high energy ball milling (attritor)

The typical mill used for these purposes has been the high energy ball mill such as tumbler ball mills, vibratory mills, planetary mills, and attritor mills (Szegvari attritor) etc. A detailed description of the different mills available for MM can be found in Suryanarayana handbook [25]; however we have discussed a brief description regarding high energy ball mills.

EUROPHYSICS LETTERS 1 April 1998 Europhys. Lett., 42 (1), pp. 91-96 (1998) Magnetic properties of Ni nanoparticles dispersed in silica prepared by high-energy ball milling

ResearchArticle Effects of Processing Parameters on the Synthesis of (K 0.5 Na 0.5)NbO 3 Nanopowders by Reactive High-Energy Ball Milling Method NguyenDucVan

high energy ball milling in malaysia companypens.co.za

Optimization of High Energy Ball Milling Parameters for

MIXER/MILL ® HIGH ENERGY BALL MILL. MIXER/MILL ® Sound Insulation Membrane Control Panel Forced Air Cooling Fan Lid Latch Safety (Interlock) BEFORE AFTER PHARMACEUTICALS SUPER ALLOY GRANITE GLASS BEFORE AFTER Timer range to 100 minutes. Optional chip* is available to extend timer range to 175 hours (10,500 minutes). Steel housing and rugged construction ensure a …

High Energy Ball Mill sun-way.com.tw

through high energy ball-milling was investigated in details. The graphene with carboxylated edge was The graphene with carboxylated edge was successfully fabricated via high energy ball-milling method in the presence of dry ice to create a high

Emax High Energy Ball Mill – Retsch

High-energy ball milling of powder B–C mixtures Request PDF

The Structure and Mechanical Properties of High-Strength

22/02/2018 · Best Price High Output ball mill design pdf manufacturer .. Pakistan ball grinding mill for cement industry new design stone ball mill for sale . mineral processing ball mill machine energy saving tubular ball mill. Quotation More. Stone Powder Machine. Stone Powder Machine, Wholesale Various High Quality Stone Powder Machine Products from . powder grinder machine ball mill stone …

Optimization of High Energy Ball Milling Parameters for

High Energy Ball Milling Manufacturer: Retsch Model: EMax Description The Emax is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time. Due to the special grinding jar geometry, the sample is thoroughly mixed which results in a narrow particle size distribution. Some

Chapter 2 High-Energy Milling springer.com

High-Energy Ball Mill Processing Edval G. Araújo, Ricardo M. Leal Neto, Marina F. Pillis, Francisco Ambrózio Filho Instituto de Pesquisas Energéticas e Nucleares IPEN-CNEN-SP,

Synthesis of Vanadium-Vanadium Carbide in-situ

Optimization of High Energy Ball Milling Parameters for

A Green Method for Graphite Exfoliation Using High-Energy Ball Milling. I. Estrada-Guel1,2, F.C. Robles-Hernandez2, J.M. Mendoza-Duarte1, R. Pérez-Bustamante1 and R.

High-energy ball milling mechanochemical processing of

Characterization of α-Fe2O3 Nanoparticles Produced by High

Effect of high-energy ball milling time on superconducting

Acceleration of Hydrogen Desorption from MgH2 by High-Energy Ball-Milling with Al2O3, TiO2, Cr2O3, and ZrO2 for Exremely Short Time Manshi Ohyanagi1, Natsuki Yamasaki1, Hiroya Tabuchi1, and Zuhair A. Munir2

Effects of Processing Parameters on the Synthesis of (K0

Cadmium Sulfide (CdS) preparation by High-Energy Ball Milling

Effect of high-energy ball milling on the electrical

How to Cite. Azhdar, B., Stenberg, B. and Kari, L. (2008), Polymer–nanofiller prepared by high-energy ball milling and high velocity cold compaction.

Effects of High-Energy Ball Milling on High Entropy Alloys

In high-energy ball milling, plastic deformation, cold-welding and fracture predominantly contribute to bring a change in size, shape and microenvironment of nanoparticles.

Effect of high-energy ball milling in the structural and

Preparation of Bi. 4. Ti. 3. O. 12 (BIT) Ceramics via a High-Energy Ball Milling Process Doped with Multi-Walled Carbon Nanotubes (MWNTs) 550 . Bi. 2. O. 3. and TiO

Optimization of High Energy Ball Milling Parameters for

HIGH ENERGY BALL MILLING gtv-mbh.com

The typical mill used for these purposes has been the high energy ball mill such as tumbler ball mills, vibratory mills, planetary mills, and attritor mills (Szegvari attritor) etc. A detailed description of the different mills available for MM can be found in Suryanarayana handbook [25]; however we have discussed a brief description regarding high energy ball mills.

High Energy Ball Milling of YAG Powders Sintering

HIGH ENERGY BALL MILLING gtv-mbh.com

The Structure and Mechanical Properties of High-Strength

High-Energy Ball Mill Processing Edval G. Araújo, Ricardo M. Leal Neto, Marina F. Pillis, Francisco Ambrózio Filho Instituto de Pesquisas Energéticas e Nucleares IPEN-CNEN-SP,

Synthesis of AlFe Intermetallic Nanoparticles by High

Evidence for self-sustained MoSi2 formation during room

through high energy ball-milling was investigated in details. The graphene with carboxylated edge was The graphene with carboxylated edge was successfully fabricated via high energy ball-milling method in the presence of dry ice to create a high

Characterization of α-Fe2O3 Nanoparticles Produced by High

Chapter 2 High-Energy Milling springer.com

X-ray diffraction analysis of tin metal powder produced by

high energy ball milling and SPS. Fig. 4. SEM images of spark plasma sintered V-V2C in-situ nanocomposites at a) 1150 °C b) 1250 °C c) 1350 °C, EDS area scan analysis of samples sintered at d) 1150 °C e) 1250 °C, and f) 1350 °C.

High-Energy Ball Milling ScienceDirect

Evidence for self-sustained MoSi2 formation during room

SURFACTANT-ASSISTED BALL MILLING A NOVEL ROUTE TO

materials Article The Structure and Mechanical Properties of High-Strength Bulk Ultrafine-Grained Cobalt Prepared Using High-Energy Ball Milling in

Low-Cost Synthesis of Highly Luminescent Colloidal Lead

Synthesis of Vanadium-Vanadium Carbide in-situ

High Energy Ball Milling of YAG Powders: Sintering Properties and Microstructural Evaluation 331 TheformationofnewY-Aphases(suchasYAG,YAP, YAM

high energy ball milling in malaysia companypens.co.za

High Energy Ball Mill The Emax is an entirely new type of ball mill which was specifically designed for high energy milling. The impressive speed of 2,000 min-1,

High-Energy Ball Mill Processing IPEN

2015; 18(5) Synthesis of SnSb 955 2 Te 4 Microplatelets by High-Energy Ball Milling 4. Conclusion SnSb 2 Te 4-based microplatelets were successfully synthesized via mechanochemical activation using

Application of high energy ball milling to the production

X-ray diffraction analysis of tin metal powder produced by

using a high energy ball milling for 30 hours. The milled specimen is analyzed with an X-Ray Diffractometer and analyzed The milled specimen is analyzed with an X-Ray Diffractometer and analyzed qualitatively and quantitatively using Rietveld method developed by Fuji Izumi.

High Energy Ball Milling NTU MSE

High-Energy Ball Mill Processing IPEN

C powders by high-energy ball milling and further heat treatment. The milling process was carried out in a planetary ball mill. Following the milling process, powder samples were heat-treated at

Preparation of Micrometer to SubmicrometerSized

Preparation of Micrometer- to Sub-micrometer-Sized Nanostructured Silica Particles Using High-Energy Ball Milling J. Eric Hampsey, Claudio L. De Castro, …

High Energy Ball Mill sun-way.com.tw

Synthesis and characterization of shape memory Nano alloy

Preparation of Micrometer to SubmicrometerSized

High Energy Ball Mill The Emax is an entirely new type of ball mill which was specifically designed for high energy milling. The impressive speed of 2,000 min-1,

Sub-micron sized Al2TiO5 powders prepared by high-energy

The Structure and Mechanical Properties of High-Strength

High Energy Ball Milling of YAG Powders: Sintering Properties and Microstructural Evaluation 331 TheformationofnewY-Aphases(suchasYAG,YAP, YAM

High Energy Ball Milling of YAG Powders Sintering

high energy ball milling and SPS. Fig. 4. SEM images of spark plasma sintered V-V2C in-situ nanocomposites at a) 1150 °C b) 1250 °C c) 1350 °C, EDS area scan analysis of samples sintered at d) 1150 °C e) 1250 °C, and f) 1350 °C.

HIGH ENERGY BALL MILLS sun-way.com.tw

Preparation of magnetite nanoparticles by high-energy

result of the capacity of high-energy ball milling to induce selenium amorphisation because of its special molecular structure that consists of helical molecular chains that are bonded together by weak van der Waals forces [22].

Preparation of Dispersion Strengthened Aluminum Alloy by

HIGH ENERGY BALL MILLING gtv-mbh.com

High-Energy Ball Mill Processing Edval G. Araújo, Ricardo M. Leal Neto, Marina F. Pillis, Francisco Ambrózio Filho Instituto de Pesquisas Energéticas e Nucleares IPEN-CNEN-SP,

High-energy ball milling of powder B–C mixtures Request PDF

High energy ball milling in high purity argon of alloys of NdFeB both with and without additions of Co and Zr, combined with suitable heat treatment, has been used to produce magnetic powders with coercivities up to 960 kA m −1 (12 kOe).

Effect of high-energy ball milling on the electrical

Effect of high-energy ball milling in the structural and

ResearchArticle Effects of Processing Parameters on the Synthesis of (K 0.5 Na 0.5)NbO 3 Nanopowders by Reactive High-Energy Ball Milling Method NguyenDucVan

Synthesis of SnSb Te Microplatelets by High-energy Ball

In this study, the heterogeneous Fenton oxidation of ciprofloxacin (CIP) in an aqueous solution was examined over the nano-sized magnetite (FeO) as a catalyst supplied through high-energy planetary ball milling process.

ball mill energy conservation pdf

Preparation of Bi4Ti3O12 (BIT) Ceramics via a High-Energy

High Energy Ball Mill sun-way.com.tw

The Emax is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within. The unique combination of high friction and impact results in extremely fine particles within.

high energy ball milling in malaysia companypens.co.za

In order to develop a high-strength aluminum alloy, alumina dispersion strengthened aluminum alloy was prepared by high energy ball milling on 2024 aluminum alloy powder in ethanol. The microstructure, particle size and distribution of the Al2O3 particles in the alloy were analyzed by FE-SEM; the mechanical properties were investigated. Results

Optimization of High Energy Ball Milling Parameters for

EFFECT OF PROCESS VARIABLES ON THE SYNTHESIS OF MGB2 BY

Hydrogen Absorption Capacity of Fe-Ti-Al Alloy Prepared by

In high-energy ball milling, plastic deformation, cold-welding and fracture are predominant factors, in which the deformation leads to a change in particle shape, cold -welding leads to an increase in particle size and fracture leads to decrease in particle sizeresulting in the formation of fine dispersed

MIXER/MILL Instrument Solutions

Preparation of Dispersion Strengthened Aluminum Alloy by

Preparation and Characterization of Hydroxyapatite/Alumina

istry, the term high-energy milling is frequently used in order to stress the character of applied milling equipments (mills) [Boldyrev 1983; Bal´aˇz 2000]. The chapter is intended as an introduction to the topic of high-energy milling and

Emax High Energy Ball Mill – Retsch

Influence of the milling parameters on the mechanical work

Synthesis of AlFe Intermetallic Nanoparticles by High

High Energy Ball Milling. In discussions on high energy ball milling, the more generic term “ball mills” is often used in place of the terms “stirred ball mills” or “Attritors,” but the differences between the types of mills are quite distinct.

HIGH ENERGY BALL MILLING gtv-mbh.com

Mechanical Synthesis of Iron and Nickel Solid Solution by

using a high energy ball milling for 30 hours. The milled specimen is analyzed with an X-Ray Diffractometer and analyzed The milled specimen is analyzed with an X-Ray Diffractometer and analyzed qualitatively and quantitatively using Rietveld method developed by Fuji Izumi.

ball mill energy conservation pdf

X-ray diffraction analysis of tin metal powder produced by

Sub-micron sized Al2TiO5 powders prepared by high-energy

High-energy ball milling is a type of mechanical grinding of materials. This process can be conducted in a dry (without solvents) or wet (with solvents) fashion. Laboratory-scale ball milling (5−100 mL scale) is a batch process, whereas industrial ball mills can be operated in a continuous mode, thus offering a very high synthesis throughput. The milling occurs due to mechanical friction

MIXER/MILL Instrument Solutions

ball mill energy conservation pdf

Acceleration of Hydrogen Desorption from MgH2 by High

ball mill energy conservation pdf . Energy Efficiency and Carbon Dioxide Emissions Reduction . September 1999. This work was supported by the Assistant Secretary of Energy Efficiency and Renewable Energy and estimated energy savings, carbon dioxide savings, investment costs, and operation and .. the cement (gypsum and anhydrite) can be done in

Synthesis and characterization of shape memory Nano alloy

High-Energy Ball Mill Processing IPEN

X-ray diffraction analysis of tin metal powder produced by high energy ball milling L. Manzato 1, Q. H. F. Rebelo 2, D.M. Trichês 2, S. M. Souza 2, M. F. de Oliveira 3

Hydrogen Absorption Capacity of Fe-Ti-Al Alloy Prepared by

Effect of high-energy ball milling time on superconducting

2015; 18(5) Synthesis of SnSb 955 2 Te 4 Microplatelets by High-Energy Ball Milling 4. Conclusion SnSb 2 Te 4-based microplatelets were successfully synthesized via mechanochemical activation using

Mechanical Synthesis of Iron and Nickel Solid Solution by

Nanoscale grains high irreversibility field and large

HIGH ENERGY BALL MILLS sun-way.com.tw

MIXER/MILL ® HIGH ENERGY BALL MILL. MIXER/MILL ® Sound Insulation Membrane Control Panel Forced Air Cooling Fan Lid Latch Safety (Interlock) BEFORE AFTER PHARMACEUTICALS SUPER ALLOY GRANITE GLASS BEFORE AFTER Timer range to 100 minutes. Optional chip* is available to extend timer range to 175 hours (10,500 minutes). Steel housing and rugged construction ensure a …

Preparation of Dispersion Strengthened Aluminum Alloy by

PDF On Aug 19, 2015, Ahmed E. Hannora and others published Synthesis of lead-borate glasses using high energy ball milling (attritor)

Synthesis and characterization of shape memory Nano alloy

The Structure and Mechanical Properties of High-Strength

Preparation and Characterization of Hydroxyapatite/Alumina

High-energy ball milling is a type of mechanical grinding of materials. This process can be conducted in a dry (without solvents) or wet (with solvents) fashion. Laboratory-scale ball milling (5−100 mL scale) is a batch process, whereas industrial ball mills can be operated in a continuous mode, thus offering a very high synthesis throughput. The milling occurs due to mechanical friction

Optimization of High Energy Ball Milling Parameters for

High-Energy Ball Mill Processing Edval G. Araújo, Ricardo M. Leal Neto, Marina F. Pillis, Francisco Ambrózio Filho Instituto de Pesquisas Energéticas e Nucleares IPEN-CNEN-SP,

high energy ball milling process pakistan Mineral

Mechanical Synthesis of Iron and Nickel Solid Solution by

High-energy ball milling mechanochemical processing of

In high-energy ball milling, plastic deformation, cold-welding and fracture are predominant factors, in which the deformation leads to a change in particle shape, cold -welding leads to an increase in particle size and fracture leads to decrease in particle sizeresulting in the formation of fine dispersed

EFFECT OF PROCESS VARIABLES ON THE SYNTHESIS OF MGB2 BY

INFLUENCE OF HIGH ENERGY BALL MILLING ON REACTIVITY IN

high-energy ball milling Chengduo Wang, Yanwei Ma, Xianping Zhang et al.-Effective carbon incorporation in MgB2 by combining mechanical milling and the glycerintreatment of boron powder Byung-Hyuk Jun, Yi-Jeong Kim, Kai Sin Tan et al.-Recent citations The reduction of optimal heat treatment temperature and critical current density enhancement of ex situ processed MgB 2 tapes using ball …

High Energy Ball Milling NTU MSE

Optimization of High Energy Ball Milling Parameters for

In order to develop a high-strength aluminum alloy, alumina dispersion strengthened aluminum alloy was prepared by high energy ball milling on 2024 aluminum alloy powder in ethanol. The microstructure, particle size and distribution of the Al2O3 particles in the alloy were analyzed by FE-SEM; the mechanical properties were investigated. Results

REINFORCEMENT ON EPOXY-BASED COMPOSITES BY

The E max is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time.

Emax High Energy Ball Mill – Retsch

Effects of Processing Parameters on the Synthesis of (K0

22/02/2018 · Best Price High Output ball mill design pdf manufacturer .. Pakistan ball grinding mill for cement industry new design stone ball mill for sale . mineral processing ball mill machine energy saving tubular ball mill. Quotation More. Stone Powder Machine. Stone Powder Machine, Wholesale Various High Quality Stone Powder Machine Products from . powder grinder machine ball mill stone …

REINFORCEMENT ON EPOXY-BASED COMPOSITES BY

Optimization of the high energy ball-milling: Modeling and parametric study Hamid Ghayoura, Majid Abdellahia,⁎, Maryam Bahmanpourb a Advanced Materials Research Center, Faculty of Materials Engineering, Najafabad Branch, Islamic Azad University, Najafabad, Iran

High Energy Ball Milling NTU MSE

Characterization of α-Fe2O3 Nanoparticles Produced by High

High Energy Ball Mill sun-way.com.tw

High Energy Ball Milling. In discussions on high energy ball milling, the more generic term “ball mills” is often used in place of the terms “stirred ball mills” or “Attritors,” but the differences between the types of mills are quite distinct.

ball mill energy conservation pdf

Cadmium Sulfide (CdS) preparation by High-Energy Ball Milling

Preparation and Characterization of Hydroxyapatite/Alumina

268 industrial processes and has an increasing importance in engineering materials, being a process that can occur either continuously or batch wiseThis technique cause changes .

HIGH ENERGY BALL MILLS sun-way.com.tw

High Energy and Reactive Milling is performed by the same processing principle where the variation is in general based on the target of processing, the transformation effect of …

Emax High Energy Ball Mill – Retsch

Hydrogen Absorption Capacity of Fe-Ti-Al Alloy Prepared by

High Energy Ball Milling & How It Works Union Process® Inc.

High energy ball milling: Mechanochemical processing of nanopowders reviews the latest techniques in mechanochemistry and how they can be applied to the synthesis and processing of various high …

Preparation and Characterization of Hydroxyapatite/Alumina

22/02/2018 · Best Price High Output ball mill design pdf manufacturer .. Pakistan ball grinding mill for cement industry new design stone ball mill for sale . mineral processing ball mill machine energy saving tubular ball mill. Quotation More. Stone Powder Machine. Stone Powder Machine, Wholesale Various High Quality Stone Powder Machine Products from . powder grinder machine ball mill stone …

HIGH ENERGY BALL MILLING gtv-mbh.com

Magnetic properties of Ni nanoparticles dispersed in

High energy ball milling in high purity argon of alloys of NdFeB both with and without additions of Co and Zr, combined with suitable heat treatment, has been used to produce magnetic powders with coercivities up to 960 kA m −1 (12 kOe).

The Structure and Mechanical Properties of High-Strength

Preparation and Characterization of Hydroxyapatite/Alumina

In order to develop a high-strength aluminum alloy, alumina dispersion strengthened aluminum alloy was prepared by high energy ball milling on 2024 aluminum alloy powder in ethanol. The microstructure, particle size and distribution of the Al2O3 particles in the alloy were analyzed by FE-SEM; the mechanical properties were investigated. Results

Preparation of Dispersion Strengthened Aluminum Alloy by

high energy ball milling process pakistan Mineral

X-ray diffraction analysis of tin metal powder produced by

2015; 18(5) Synthesis of SnSb 955 2 Te 4 Microplatelets by High-Energy Ball Milling 4. Conclusion SnSb 2 Te 4-based microplatelets were successfully synthesized via mechanochemical activation using

High Energy Ball Milling & How It Works Union Process® Inc.

High Energy Ball Milling NTU MSE

Low-Cost Synthesis of Highly Luminescent Colloidal Lead

The Emax is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within. The unique combination of high friction and impact results in extremely fine particles within.

Preparation of magnetite nanoparticles by high-energy

HIGH ENERGY BALL MILLS sun-way.com.tw

high energy ball milling and SPS. Fig. 4. SEM images of spark plasma sintered V-V2C in-situ nanocomposites at a) 1150 °C b) 1250 °C c) 1350 °C, EDS area scan analysis of samples sintered at d) 1150 °C e) 1250 °C, and f) 1350 °C.

High-Energy Ball Mill Processing IPEN

In order to develop a high-strength aluminum alloy, alumina dispersion strengthened aluminum alloy was prepared by high energy ball milling on 2024 aluminum alloy powder in ethanol. The microstructure, particle size and distribution of the Al2O3 particles in the alloy were analyzed by FE-SEM; the mechanical properties were investigated. Results

Chapter 2 High-Energy Milling springer.com

Characterization of α-Fe2O3 Nanoparticles Produced by High Energy Ball Milling O. M. LEMINE*1, A.ALYAMANI2, M. SAJIEDDINE3 AND M.BOUOUDINA4 1 Physics Department, College of Sciences, Imam University, Riyadh, Saudi Arabia.

(PDF) Synthesis of lead-borate glasses using high energy

Nanoscale grains high irreversibility field and large

High-energy ball milling of powder B–C mixtures Request PDF

PDF On Aug 19, 2015, Ahmed E. Hannora and others published Synthesis of lead-borate glasses using high energy ball milling (attritor)

High-Energy Ball Milling ScienceDirect

Magnetic properties of Ni nanoparticles dispersed in

customer magazine issue 39 planetary ball mill pm 100 mixer mill cryomill mm 400 high energy ball mills grinding and particle sizing on a nanoscale

X-ray diffraction analysis of tin metal powder produced by

High Energy Ball Milling of YAG Powders Sintering

High-energy ball milling of powder B–C mixtures Request PDF

using a high energy ball milling for 30 hours. The milled specimen is analyzed with an X-Ray Diffractometer and analyzed The milled specimen is analyzed with an X-Ray Diffractometer and analyzed qualitatively and quantitatively using Rietveld method developed by Fuji Izumi.

High Energy Ball Milling of YAG Powders Sintering

Preparation of Micrometer- to Sub-micrometer-Sized Nanostructured Silica Particles Using High-Energy Ball Milling J. Eric Hampsey, Claudio L. De Castro, …

Preparation and Characterization of Hydroxyapatite/Alumina

istry, the term high-energy milling is frequently used in order to stress the character of applied milling equipments (mills) [Boldyrev 1983; Bal´aˇz 2000]. The chapter is intended as an introduction to the topic of high-energy milling and

High-energy ball milling mechanochemical processing of

The typical mill used for these purposes has been the high energy ball mill such as tumbler ball mills, vibratory mills, planetary mills, and attritor mills (Szegvari attritor) etc. A detailed description of the different mills available for MM can be found in Suryanarayana handbook [25]; however we have discussed a brief description regarding high energy ball mills.

Characterization of α-Fe2O3 Nanoparticles Produced by High

The E max is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time.

INFLUENCE OF HIGH ENERGY BALL MILLING ON REACTIVITY IN

mechanical alloying using high energy ball mill. Ball to powder ratio, milling medium, and speed of ball mill Ball to powder ratio, milling medium, and speed of ball mill are important parameters which influence effectiveness of milling process.

High-Energy Ball Milling ScienceDirect

Optimization of High Energy Ball Milling Parameters for

High Energy Ball Milling Manufacturer: Retsch Model: EMax Description The Emax is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time. Due to the special grinding jar geometry, the sample is thoroughly mixed which results in a narrow particle size distribution. Some

Characterization of α-Fe2O3 Nanoparticles Produced by High

(PDF) Synthesis of lead-borate glasses using high energy

The Emax is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within. The unique combination of high friction and impact results in extremely fine particles within.

HIGH ENERGY BALL MILLING gtv-mbh.com

Synthesis and characterization of shape memory Nano alloy

Acceleration of Hydrogen Desorption from MgH2 by High

PDF On Aug 19, 2015, Ahmed E. Hannora and others published Synthesis of lead-borate glasses using high energy ball milling (attritor)

High Energy Ball Mill sun-way.com.tw

A Green Method for Graphite Exfoliation Using High-Energy

Synthesis and characterization of shape memory Nano alloy

J. Liu et al. /Science of Sintering, 48 (2016) 353-362 _____ 354 milled mixtures of Mg(OH)2 and Al(OH)3 after over 15 min of calcination at 900 °C.

Evidence for self-sustained MoSi2 formation during room

ResearchArticle Effects of Processing Parameters on the Synthesis of (K 0.5 Na 0.5)NbO 3 Nanopowders by Reactive High-Energy Ball Milling Method NguyenDucVan

Effects of Processing Parameters on the Synthesis of (K0

High energy ball milling in high purity argon of alloys of NdFeB both with and without additions of Co and Zr, combined with suitable heat treatment, has been used to produce magnetic powders with coercivities up to 960 kA m −1 (12 kOe).

MIXER/MILL Instrument Solutions

Milling conditions High-Energy Ball Milling Planetary mill Retsch P100 Stainless steel vial 250ml Ball / powder ratio 5:1 Ball (stainless steel) size 10 mm

Preparation of magnetite nanoparticles by high-energy

Effect of high-energy ball milling in the structural and

Acceleration of Hydrogen Desorption from MgH2 by High-Energy Ball-Milling with Al2O3, TiO2, Cr2O3, and ZrO2 for Exremely Short Time Manshi Ohyanagi1, Natsuki Yamasaki1, Hiroya Tabuchi1, and Zuhair A. Munir2

A Green Method for Graphite Exfoliation Using High-Energy

high energy ball milling process pakistan Mineral

Effects of High-Energy Ball Milling on High Entropy Alloys

using a high energy ball milling for 30 hours. The milled specimen is analyzed with an X-Ray Diffractometer and analyzed The milled specimen is analyzed with an X-Ray Diffractometer and analyzed qualitatively and quantitatively using Rietveld method developed by Fuji Izumi.

Sub-micron sized Al2TiO5 powders prepared by high-energy

High-Energy Ball Mill Processing IPEN

• The Bond ball mill work index (BWI) trends strongly upwards from north to south in the P zone, is relatively consistent in the O zone, is much harder in the south H …

High-energy ball milling mechanochemical processing of

High-energy ball milling is a type of mechanical grinding of materials. This process can be conducted in a dry (without solvents) or wet (with solvents) fashion. Laboratory-scale ball milling (5−100 mL scale) is a batch process, whereas industrial ball mills can be operated in a continuous mode, thus offering a very high synthesis throughput. The milling occurs due to mechanical friction

Influence of the milling parameters on the mechanical work

Optimization of the high energy ball-milling Modeling and

In high-energy ball milling, plastic deformation, cold-welding and fracture predominantly contribute to bring a change in size, shape and microenvironment of nanoparticles.

The Structure and Mechanical Properties of High-Strength

Emax High Energy Ball Mill – Retsch

Supercond. Sci. Technol. 25 (2012) 035018 C Wang et al microstructure and non-metallic (mainly oxygen) content of the low purity boron powders with the same purity have an

High Energy Ball Milling NTU MSE

Structural Analysis of PbO-B OZnO Glasses by High Energy

Evidence for self-sustained MoSi2 formation during room

22/02/2018 · Best Price High Output ball mill design pdf manufacturer .. Pakistan ball grinding mill for cement industry new design stone ball mill for sale . mineral processing ball mill machine energy saving tubular ball mill. Quotation More. Stone Powder Machine. Stone Powder Machine, Wholesale Various High Quality Stone Powder Machine Products from . powder grinder machine ball mill stone …

Hydrogen Absorption Capacity of Fe-Ti-Al Alloy Prepared by

HIGH ENERGY BALL MILLING – A PROMISING ROUTE FOR PRODUCTION OF TAILORED THERMAL SPRAY CONSUMABLES A. WANK, B. WIELAGE Institute of Composite Materials, Chemnitz University of Technology, Chemnitz, Germany

ball mill energy conservation pdf

Acceleration of Hydrogen Desorption from MgH2 by High

In order to develop a high-strength aluminum alloy, alumina dispersion strengthened aluminum alloy was prepared by high energy ball milling on 2024 aluminum alloy powder in ethanol. The microstructure, particle size and distribution of the Al2O3 particles in the alloy were analyzed by FE-SEM; the mechanical properties were investigated. Results

Low-Cost Synthesis of Highly Luminescent Colloidal Lead

High energy ball milling: Mechanochemical processing of nanopowders reviews the latest techniques in mechanochemistry and how they can be applied to the synthesis and processing of various high …

Preparation and Characterization of Hydroxyapatite/Alumina